Normal

0

false

false

false

EN-US

X-NONE

AR-SA

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:"Table Normal";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-parent:"";

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin-top:0in;

mso-para-margin-right:0in;

mso-para-margin-bottom:8.0pt;

mso-para-margin-left:0in;

line-height:107%;

mso-pagination:widow-orphan;

font-size:11.0pt;

font-family:"Calibri",sans-serif;

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;

mso-bidi-font-family:Arial;

mso-bidi-theme-font:minor-bidi;}

Silt Density Index (SDI) Test

Silt Density Index (SDI) Test

A Critical Tool for Water Treatment Water is a precious resource, and its quality is essential for human health and well-being. As such, water treatment plants rely on a variety of methods to remove impurities and contaminants from water before it is distributed to consumers. One critical tool in this process is the Silt Density Index (SDI) test, which helps to evaluate the effectiveness of water treatment filters in removing particulate matter..

Normal

0

false

false

false

EN-US

X-NONE

AR-SA

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:"Table Normal";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-parent:"";

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin-top:0in;

mso-para-margin-right:0in;

mso-para-margin-bottom:8.0pt;

mso-para-margin-left:0in;

line-height:107%;

mso-pagination:widow-orphan;

font-size:11.0pt;

font-family:"Calibri",sans-serif;

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;

mso-bidi-font-family:Arial;

mso-bidi-theme-font:minor-bidi;}

What is the SDI Test?

What is the SDI Test?

The SDI test is a measure of the filterability of water through a filter membrane, typically used in the water treatment industry to evaluate the performance of reverse osmosis (RO) and ultrafiltration (UF) membranes, as well as other types of filters.

The test involves filtering a known volume of fluid through a 0.45-micron filter membrane, and measuring the pressure drop across the filter over time.

The test is typically conducted at a pressure of 27.6 psi (1.9 bar) and a temperature of 68°F (20°C).

Normal

0

false

false

false

EN-US

X-NONE

AR-SA

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:"Table Normal";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-parent:"";

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin-top:0in;

mso-para-margin-right:0in;

mso-para-margin-bottom:8.0pt;

mso-para-margin-left:0in;

line-height:107%;

mso-pagination:widow-orphan;

font-size:11.0pt;

font-family:"Calibri",sans-serif;

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;

mso-bidi-font-family:Arial;

mso-bidi-theme-font:minor-bidi;}

Why is the SDI Test Important?

Why is the SDI Test Important?

The SDI test is a critical tool in water treatment, as it helps to evaluate the effectiveness of filters in removing particulate matter.

Particulate matter, such as dirt, silt, and other suspended solids, can clog filters, reduce the flow of water, and affect the overall quality of treated water.

By testing the SDI value of a filter, water treatment plants can determine when a filter needs to be cleaned or replaced, ensuring that the quality of treated water remains high.

In addition, the SDI test can help to identify potential problems in the water treatment process, such as the presence of colloidal particles, which can be difficult to remove with traditional filtration methods. By detecting these issues early, water treatment plants can take corrective action and maintain the quality of treated water.

How is the SDI Test Performed?

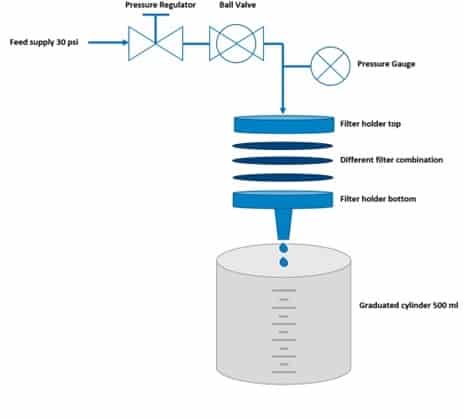

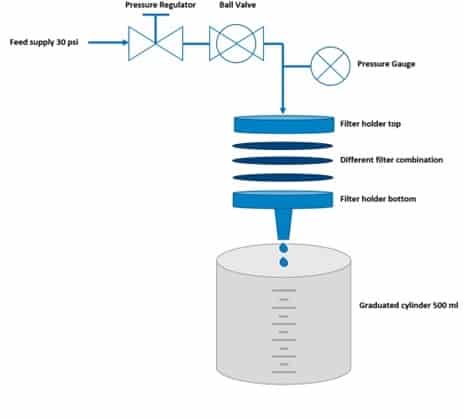

The SDI test is relatively straightforward and can be performed using standard laboratory equipment. Here are the basic steps involved in conducting an SDI test:

1. Collect a representative water sample from the source being treated.

2. Filter a known volume of the water sample through a 0.45-micron filter membrane, using a pressure of 27.6 psi (1.9 bar).

3. Measure the pressure drop across the filter over time, typically 15 minutes.

4. Calculate the SDI value by dividing the initial pressure drop by the pressure drop after 15 minutes.

Interpreting the Results

The SDI value is expressed as a number between 0 and 5, with a lower value indicating better filterability. Generally, an SDI value of 1 or lower is considered acceptable for most water treatment applications. However, some applications, such as RO and UF membrane filtration, may require even lower SDI values to achieve optimal performance.

If the SDI value is too high, it may indicate that the filter is becoming clogged with particulate matter and needs to be cleaned or replaced. In some cases, the high SDI value may be due to the presence of colloidal particles, which can be difficult to remove with traditional filtration methods.

Conclusion

In conclusion, the SDI test is a critical tool in water treatment, helping to evaluate the effectiveness of filters in removing particulate matter and identifying potential problems in the treatment process. By conducting regular SDI testing, water treatment plants can ensure that the quality of treated water remains high, providing safe and clean water for consumer